GI Pipes

Price 60 INR/ Kilograms

MOQ : 50 Kilograms

GI Pipes Specification

- Alloy

- Galvanized Iron

- Surface Treatment

- Galvanized

- Usage

- Construction, Plumbing, Water Supply

- Product Type

- GI Pipe

- Grade

- IS 1239/IS 3589

- Shape

- Rod

- Thickness

- 2.5 mm - 6 mm

- Length

- 6 m - 12 m

- Width

- Custom

- Application

- Industrial, Agricultural, Domestic

- Color

- Silver

- Outer Diameter

- 15 mm - 200 mm

- Length Tolerance

- +/- 5 mm

- Tensile Strength

- 300-500 MPa

- Pipe Class

- A/B/C Class

- Connection Type

- Welded / Seamless

- Rust Resistance

- High

- End Connection

- Plain End / Threaded End

- Packaging Type

- Bundles

- Standard

- ASTM, IS, BS

GI Pipes Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 250 Kilograms Per Week

- Delivery Time

- 5-7 Days

- Main Domestic Market

- Karnataka

About GI Pipes

Our company is highly appreciated as the best and trustworthy Supplier of GI Pipes. These pipes are processed by utilizing the finest quality materials and sophisticated tools & techniques, under the instructions of our team of adroit and talented professionals. It is widely used in construction, agricultural and industrial applications and highly admired for its easy & accurate clamping, flawless performance, high utility and durability. Moreover, you can avail the offer of GI Pipes in various specifications at very reasonable rates.

Features:

- Ruggedness

- Precise design

- Durable finish

Superior Rust-Resistant Performance

Manufactured using advanced galvanizing techniques, our GI pipes withstand the harshest environments thanks to their exceptional rust resistance. This makes them ideal for both outdoor and indoor applications, ensuring long-term reliability in construction, plumbing, and water supply systems. The galvanized surface acts as a protective barrier against corrosion, reducing maintenance needs over time.

Versatile Applications Across Industries

With compliance to IS 1239 and IS 3589 grades, our pipes are widely suitable for industrial, agricultural, and domestic uses. The customizable diameters and thicknesses make them perfect for a broad array of projects, including pipelines, scaffolding, irrigation systems, and residential water distribution, accommodating the demands of diverse sectors.

FAQs of GI Pipes:

Q: How do the GI pipes resist corrosion in demanding environments?

A: These GI pipes undergo a thorough galvanizing process during manufacturing, creating a zinc-coated barrier that effectively resists moisture and environmental elements. This coating protects the underlying steel from rust and extends the lifespan of the pipes, making them suitable for outdoor, industrial, and water transportation purposes.Q: What are the available end connection types for these pipes?

A: Our GI pipes are offered with either plain ends for welding and further processing or threaded ends for quick and secure joint assembly. This flexibility allows customers to select the right connection based on the installation requirements, whether for plumbing, construction, or other uses.Q: When should I choose welded versus seamless GI pipes?

A: Welded GI pipes are generally chosen for standard water supply, construction, and plumbing tasks, as they are cost-effective and readily available. Seamless pipes are preferred for situations needing higher pressure tolerance and a flawless internal surface, such as specialized industrial or process applications.Q: Where are these galvanized pipes typically used?

A: These pipes find extensive use in construction frameworks, water supply systems, agricultural irrigation, and a variety of domestic and industrial piping networks. Their adaptability to different diameters and thicknesses ensures suitability for both small-scale and large-scale projects.Q: What standards and grades are the pipes manufactured to?

A: Our GI pipes are manufactured in accordance with global and Indian standards such as ASTM, IS, and BS, specifically meeting IS 1239 and IS 3589 grades. This ensures uniformity, strength, and compatibility for various technical applications.Q: How does the packaging and length tolerance benefit buyers?

A: The pipes are bundled securely to facilitate safe transportation and handling. With a length tolerance of +/- 5 mm, buyers can be assured of accurate, on-site fitting, minimizing the need for further adjustments and reducing installation time.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Galvanised Materials Category

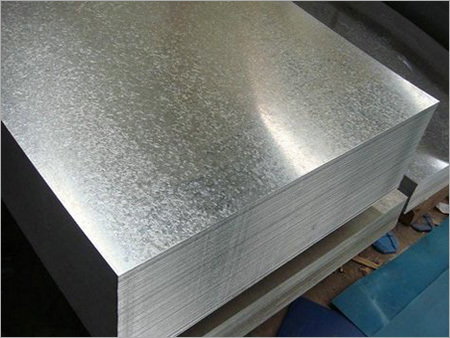

Galvanized Plain Sheets

Price Range 2500.00 - 7500.00 INR

Minimum Order Quantity : 50 Tons

Shape : Rod

"We want bulk order inquiries mainly from South India"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free